The most common points of water ingress are likely between adjacent concreting or where mechanical elements form part of the concreting. To prevent this unwanted water damage from occurring, waterstops are specifically designed and installed at every joint in the concrete.

The best waterstops are made from high-grade PVC and can be bought and installed with ease at your choice waterproofing contractor in Sydney. Keep reading to learn more about waterstops before making your purchase.

Understanding what a waterstop is

Waterstops, although diverse in shape and size, all work to achieve the same goal – to seal a construction joint to create a waterproof barrier. Generally, how it works is to expose a material to either water or heat which then expands into the concrete, completely sealing the joint, thus forming a completely waterproof barrier.

A waterstop installed in concrete joints is an essential component of the overall waterproofing design to protect specific portions of the concrete structure. Waterstops are a good best-practice design for construction and any other waterproofing project.

The uses of waterstops to aid waterproofing contractors in Sydney

As with all other materials, concrete will expand and contract as temperatures rise and fall. In order to allow for this movement, expansion joints must be installed at certain intervals within any concrete structure.

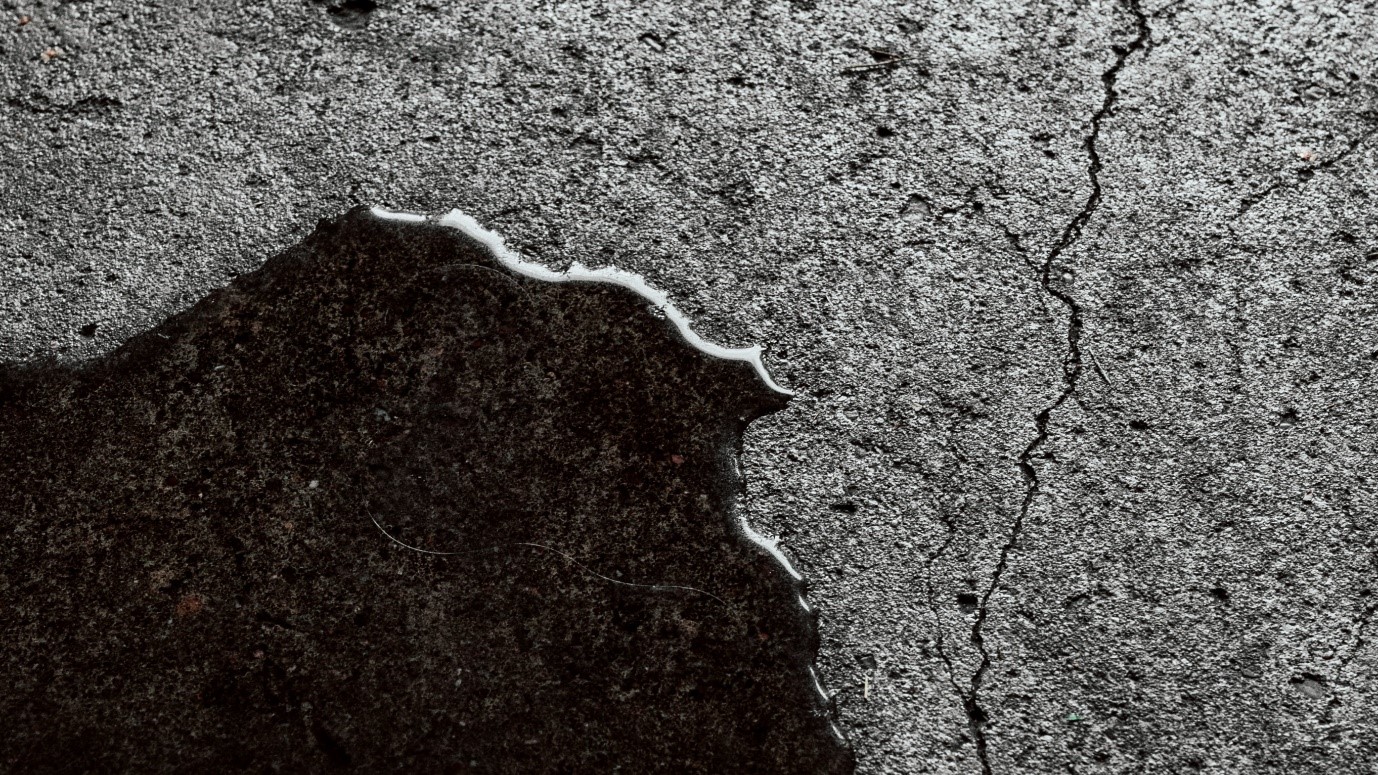

An imperfectly installed expansion joint will lead to cracking, with these joints then letting water into the concrete, opening it up to further damage. But this time the damage will occur on the inside of the slab, rather than on its surface.

Installing waterstops in the joint areas is a way to dramatically extend the life of your concrete. Despite being a tough material, concrete can quickly degrade when in contact with water. If your concrete isn’t well sealed, moisture will gradually seep in, cracking the concrete as it expands and contracts with temperature, rusting your concrete reinforcements and promoting the growth of mould. The joints of your concrete are perhaps the most vulnerable part of its construction.

By strengthening them with the right preventive measures, you’re adding years – if not decades – to the life of your slab.

Applications of waterstops

A waterstop is appropriate wherever you find a concrete joint that could possibly come into contact with water. Areas of application include:

• Water towers, water tanks and reservoirs

• Dams, canals, culverts and spillways

• Basements and slab on grade

• Tunnels and underground vaults

• Elevator and equipment pits

• Roof decks and podium areas

• Parking structures

Find out more about waterproofing solutions. At Titan waterproofing, our team has the knowledge and expertise to install waterstops effectively. Additionally, we also do other concrete waterproofing work, including torch on membrane, liquid membrane and epoxy coating.

Call our friendly team for a quote today, 1300 761 219.